Precision Tubes Fabrication & Hydraulic

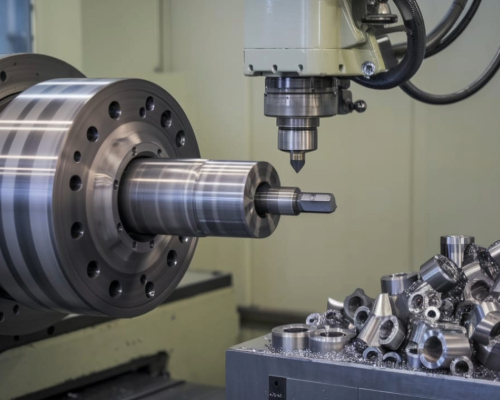

Precision Tube Fabrication plays a vital role in producing high-accuracy tubular components that meet stringent dimensional tolerances and performance standards. These tubes are typically manufactured using cold-drawing techniques and are known for their tight tolerances, uniform wall thickness, and superior surface finish. In hydraulic systems, precision tubes are widely used for conveying pressurized fluids, ensuring leak-proof performance and operational efficiency. They are made from high-grade carbon steel or stainless steel to withstand high pressure and resist corrosion. Applications span across automotive, industrial machinery, aerospace, and fluid power systems, where durability and precision are non-negotiable. Custom fabrication options like bending, cutting, flaring, and end-forming make them ideal for tailored hydraulic solutions.

Precision Manufacturing: Cold-drawn tubes ensure high accuracy and smooth finish.

Durable Materials: Made from carbon steel, stainless steel, or alloy steel for high pressure resistance.

Hydraulic Applications: Used in brake lines, fuel systems, hydraulic cylinders, and fluid transfer systems.

Performance Features: Leak-proof, consistent wall thickness, corrosion-resistant.

Custom Fabrication: Supports bending, flaring, cutting, and end-forming as per system needs.

Standard Compliance: Meets DIN, ASTM, EN, and ISO specifications.

Contact Us

+91 8726050607